The Significance of Fermentation

Fermentation, the pillar of metabolic processes that has been a part of human civilization for centuries, has had a profound impact on the formation of cultural practices and technology innovation. Its practices span centuries-old artisan methods, like production of leavened bread, to contemporary industrial ones that produce complex fermented beverages such as beer.

In the very heart of fermentation is contained the age-old equation, a concept so simple, but so effective in explaining how organisms use and convert latent sugar energy into vital food and useful products without the presence of oxygen. This process is the foundation of modern industrial practice tying together a variety of areas ranging from mass food processing to the development of green sources of energy and innovations in the creation of biofuels.

A deep understanding of this fermentation equation allows industries to optimize performance, reduce waste, and create a more sustainable relationship with the planet, ultimately opening a pathway for fruitful coexistence between human practices and nature.

The Core Fermentation Equation

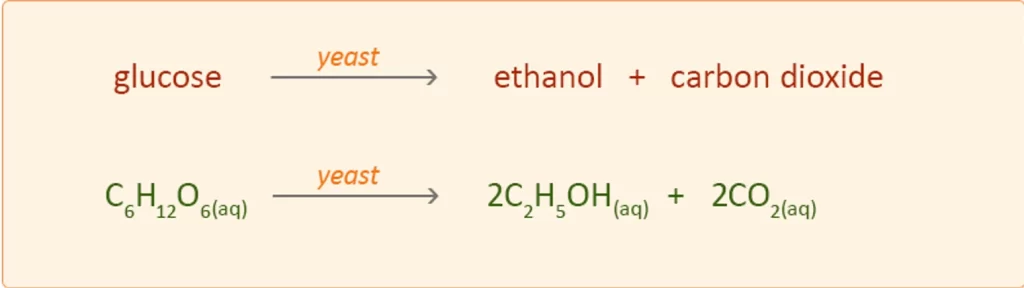

The famous fermentation process under discussion is alcoholic one when glucose converts to ethanol and carbon dioxide:

C₆H₁₂O₆ → 2 C₂H₅OH + 2 CO₂

In this reaction:

C₆H₁₂O₆ represents glucose.

C₂H₅OH denotes ethanol.

CO₂ is carbon dioxide.

This fermentation reaction formula illustrates the step by step sequence in which yeast converts glucose under anaerobic conditions to produce ethanol and carbon dioxide. The fundamental proposition is significant to the traditional brewing industry and to the large-scale production of bioethanol as a greener alternative to conventional petroleum-based fuels.

In-depth knowledge of the bio- conversion of glucose in yeasts is pivotal to improving the fermentation processes that will enable the production of many products including alcoholic drinks and bioethanol. The breakdown of glucose conducted by yeast is extremely important both in ethanol production and for international efforts to utilize renewable and clean resources, which will ensure reducing the negative effects of climate change and securing future energy supplies.

Variations of the Fermentation Equation

Different organisms and conditions lead to variations in the fermentation reaction formula:

Lactic Acid Fermentation:

- Active in muscle-cells and in different bacterial species.

- Equation: C₆H₁₂O₆ → 2 C₃H₆O₃

- The process involves this conversion of glucose to lactic acid that is necessary for making yogurt and generation of energy by muscles in rigorous activities.

Sucrose Fermentation:

- The first step is the splitting of the sucrose into glucose and fructose.

- Equation: C₁₂H₂₂O₁₁ + H₂O → 2 C₆H₁₂O₆

- This is then followed by the normal steps of glucose fermentation.

- Such adaptability shows the flexibility of the fermentation equation when used in different living things.

The Biochemical Pathway

The reaction that is given by the equation of fermentation is a summation of several successive biochemical reactions.

- Glycolysis:

The process of breakdown of glucose produces pyruvate, along with the formation of ATP and NADH.

- Fermentation:

Under anaerobic conditions pyruvate would be converted to NAD⁺ for fermentation and glycolysis would be sustained.

Although glycolysis with fermentation generates comparatively small amounts of ATP when compared to aerobic metabolism, it is an essential method of energy supply in anaerobic conditions.

The Industrial Ramifications of the Fermentation Equation

A deeper insight into the equation of fermentation has led to various industrial applications:

- Alcoholic Beverage Production: At the center of production of beer, wine and spirits, yeast fermentation technology demonstrates the intricate and refined processes needed to transform raw ingredients into the enticing and delightful products we have become accustomed to. This demanding method calls for attentive monitoring during fermentation to ensure that the final products are characterized by their unique taste and alcohol compositions making them unique in nature and quality.

- Biofuel Generation: As a production process, conversion of biomass to ethanol is a pioneering idea of producing renewable energy which has a lot of prospects in combating environmental issues and bringing down our dependence on fossil fuels. This method is an innovation, as it makes use of natural sources to promote a sustainable future, which emphasizes the important contribution biofuel generation makes in meeting the ever-increasing energy demands of society.

- Food Industry: In the continuously changing food industry, fermentation is a precious approach that adds vivid flavors to a wide range of products from the creaminess of yogurt all the way to the sharpness of sauerkraut. Fermentation does not only make food taste better and have a better nutritional profile, but it also protects ingredients, resulting in complex flavor and texture that define the art of food and affirms fermentation’s basic role within industries.

- Pharmaceuticals: Investigating pharmaceutical practices reveals this fascinating blend of science and nature, and microbial fermentation is identified as the critical process underlying lifesaving antibiotic production significantly contributing to public health and medical results. The mutualistic activity amongst microorganisms during this process demonstrates the pharmaceutical industry’s efforts to utilize the strength of biology for producing essential drugs which will indicate the scientific advance and medical triumph, therefore justifying the basic importance of microbial fermentation in pharmaceutical production.

These applications highlight the economic and practical significance of the fermentation reaction formula.

The Role of Bioreactors

Companies striving to maximize fermentation results frequently rely on highly developed bioreactors, complex systems that enable precise control of the environmental factors for effective microbial growth and the constant production of goods. BaiLun Bio is a company that is known for its specialization at developing custom bioreactor technologies that can be adjusted to specific requirements of different types of fermentation processes, and to deliver constant and scalable results.

It is through companies leveraging the most recent bioreactor engineering and technological innovations that consistent quality and high yield can be achieved in all industrial processes, thus contributing to the success and expansion of many fermentations based industries.

Challenges and Considerations

The fermentation equation provides a basic insight, however, in real application such factors must be considered:

- Substrate concentration: Substrate concentration exerts a significant impact on determining reaction rates, as well as the overall final product’s yield in fermentation. The level of available substrate plays huge role in the success and efficiency of fermentation and thus requires regular control and adjustment when required. Besides, the dynamic relationship between substrate availability and enzyme functionality has a drastic effect on how a fermentation will unfold.

- pH and Temperature: It is important to ensure that pH and temperature are well controlled to bring about high levels of microbial activity and the best possible output of fermentation. The exact balance of these elements is the critical factor of the success of fermentation; their interplay ultimately defines the overall quality and production volume of the end-product.

- Oxygen Concentrations: Subparts of oxygen concentrations can still play a big role in the manner of how fermentation is done. Although fermentation is typically based on anaerobic conditions, minimal exposure to oxygen can disrupt the metabolic processes of microorganisms and thus degrade the performance and quality of the fermentation. Due to this, it is critical to have a close control of oxygen levels to ensure that one can achieve the best fermentation results. Producers are able to increase the yield and quality of their products through careful management of these vital variables, and it also supports a high-quality process.

Final Thoughts

With the unravelling of the complexity of chemical and biological interaction, the fermentation equation transcends the realms of simple mathematics pointing to an essential perspective that connects our life to the crux of life’s mysteries. The fundamental aspects of fermentation, anchoring us in antiquity and into the modern era of biotech and sustainability, have always shined forward the path to continued advancement and innovation.

The unrelenting flow of conversion from sugars to alcohols, acids, and so on, is an excellent metaphor for the manner through which society has developed, changed, and evolved, leveraging our efforts with the basic drivers of life. As, we explore new frontiers in biotechnology and sustainable production, the principles encapsulated in the fermentation reaction formula will remain central to our progress.

FAQs

- What is the fermentation equation?

The expression of fermentation refers to the series of chemical reactions by which glucose (C₆H₁₂O₆) is converted to ethanol, carbon dioxide or lactic acid in the absence of oxygen, depending on the type of fermentation. For a specific example, the usual chemical formula for acquiring ethanol through fermentation is:

C₆H₁₂O₆ → 2 C₂H₅OH + 2 CO₂.

- How does fermentation differ from respiration?

Fermentation and respiration are both energy production processes using glucose but depend on the availability of oxygen to differ. Fermentation occurs without oxygen (in anaerobic environment), while the aerobic respiration requires the use of oxygen to completely metabolize the glucose into carbon dioxide and water. This means, therefore, that fermentation produces less energy molecules and is not as efficient as Aerobic respiration.

- Why is the knowledge of the fermentation equation essential to the brewing and biofuel production industries?

Whereas in the brewing, winemaking and biofuel industries, it is essential to understand the equation for fermentation. In the manufacture of beer and wine yeast converts sugars in grains or fruits to alcohol and carbon dioxide, the key ingredient in these beverages through fermentation reaction formula. Biofuel processes can be used to produce ethanol (a renewable source of energy) from the fermentation of plant material by microorganisms.